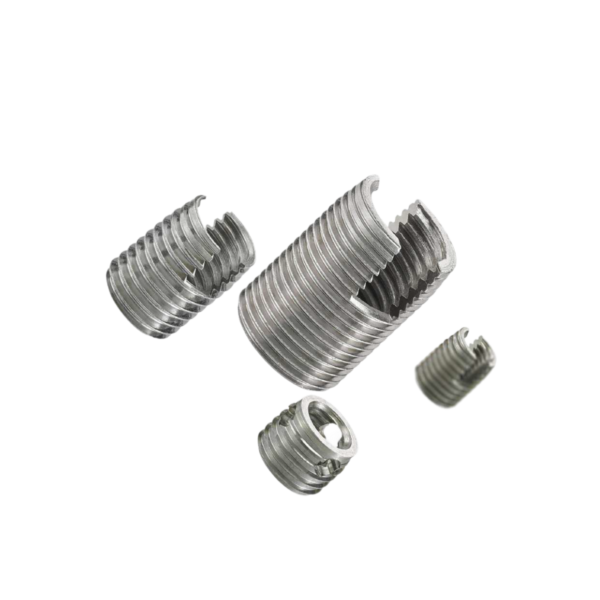

AMECOIL® Wire Thread Inserts, high-strength mechanical fasteners

For more than 45 years, AMECA has been the French specialist in the design and manufacture of Wire Thread Inserts. Used in all industrial sectors , AMECOIL® Wire Thread Inserts are recognised for ensuring reliable and durable assemblies.

Repair or reinforce tapping with AMECOIL® Wire Thread Inserts

AMECOIL® Wire Thread Inserts are designed for two main uses:

- Repairing worn or damaged thread

In the event of damaged or stripped or threads, AMECOIL® Wire Thread Insert allows the original thread to be restored without changing the final diameter of the screw. It is a simple, reliable and economical solution for extending the service life of parts and limiting re-tapping operations. AMECOIL® repair kits are specially designed for this.

- Create reinforced and durable thread

In a new configuration, AMECOIL® Wire Thread Inserts make it possible to secure assemblies in critical environments: high temperatures, vibrations, corrosion, significant mechanical stresses…

They improve tensile strength, ensure even load distribution and provide a stronger thread than the original one, even in aluminium or cast iron.

Technological advantages of the AMECOIL® Wire Thread Insert

Our range of Wire Thread Inserts

AMECOIL® SR

The AMECOIL® SR Wire Thread Insert offers a reduced diameter notch coil designed to facilitate the installation.

- Sizes: from M2 to M100 – from 2-56 to 3½”

- UNC, UNF, BSP, BSW, BSF, NPT metric

- Various materials and coatings available

All technical options are detailed in our AMECOIL® catalogue.

AMECOIL® SR SCREW-LOCKING

The AMECOIL® AF Wire Thread Insert offers the same performance as an AMECOIL® SR, with an integrated screw lock system that prevents unscrewing due to vibration and dynamic loads, and is distinguished by its red colour for quick identification.

- Dimensions: from M2 to M100 – from 2-56 to 3½”

- UNC, UNF, BSP, BSW, BSF, NPT metric

- Various materials and coatings available

All technical options are detailed in our AMECOIL® catalogue.

AMECOIL® STRIP FEED

Thread inserts packaged on a strip feed to improve and working conditions.

All technical options are detailed here

AMECOIL® FREE / TANGLESS®

They have the same characteristics as AMECOIL® without a tang, making it an ideal solution for blind holes and sensitive applications such as Aerospace and electronics, when no FOD is essential. However, installing them requires a special tooling more complex than the one used for the standard AMECOIL® Tanged Wire Thread Inserts.

- Sizes: from M2.5 to M12 – from 2-56 to 3/8-16

- UNC, UNF metric

- Various materials and coatings available

All technical options are detailed in our AMECOIL® FREE / TANGLESS® catalogue

AMELOCK

Self-locking nut resulting from the assembly of an AMECOIL® SCREW-LOCK thread in a nut.

The mechanical characteristics obtained are equivalent to ISO 2320 (steel screws).

All technical options are detailed here

AMECOIL® repair kits

Our boxes are available in several sizes, in Standard or Industrial models, as well as in single-dimensional or multi-dimensional versions.

Discover all the options available in our Repair kits catalogue

AMECOIL® Wire Thread Inserts: sizes, threads and materials available

To meet the diversity of industrial applications, AMECOIL® Wire Thread Inserts are available in a wide choice of diameters, shapes and materials.

Available sizes: from M1.6 to M100 – from 2-56 to 3½”

Threads offered: metric, UNC, UNF, BSP, BSW, BSF

Each version is designed to adapt to the specific requirements of your assembly, whether for repair, reinforcement or original production.

We also offer several technical materials and coatings to optimise compatibility with your environments (temperature, corrosion, fatigue, etc.).

To facilitate identification and traceability, a specific dying of the inserts can be managed on request.

Want to discover all available options?

Installation systems for Wire Thread Inserts

To ensure precise, fast and durable installation of your AMECOIL® Wire Thread Inserts, it is essential to use a suitable installation system. AMECA offers a wide range of manual, semi-automatic and automatic tools designed to meet the requirements of maintenance workshops and production lines.

Each tool is designed to optimise installation, prevent misalignment errors and ensure the performance of reinforced tapping. Discover our installation systems.

High-performance wire thread inserts for demanding industries

Aware of the specific requirements of each industrial sector, we work closely with our customers to adapt our AMECOIL® inserts to their technical, standard and environmental constraints.

Our customised approach allows us to provide reliable and compliant fastening solutions, perfectly integrated with the specific needs of each application.

Aerospace

Aerospace

AMECOIL® Wire Thread Inserts are used in major Aerospace programmes. They are used in engines, cabin fittings, air bleed systems, avionics systems, etc.

Defense

Defense

AMECOIL® Wire Thread Inserts are used in the manufacture of military vehicles.

Energy

Energy

The Wire Thread Inserts are used in gas and hydrogen turbines.

Nuclear

Nuclear

AMECOIL® Wire Thread Insert are used in vitrified waste containers and on steam generators and pressurisers for PWR.